Oil Water Separator

What Is an Oil/Water Separator?

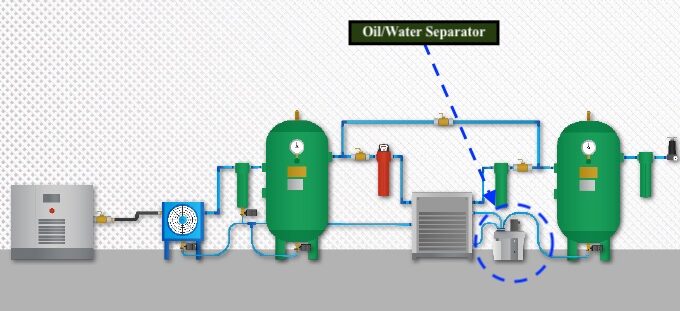

In industrial compressed air systems, condensate is an unavoidable byproduct. This condensate typically contains both water and lubricating oil, especially in systems using oil-lubricated compressors. Discharging this oily wastewater directly into the environment is illegal and harmful. That’s where the oil/water separator comes in – a vital device that separates oil from water in condensate, making it safe for disposal and helping businesses comply with environmental regulations.

How is Oil/Water Separator work?

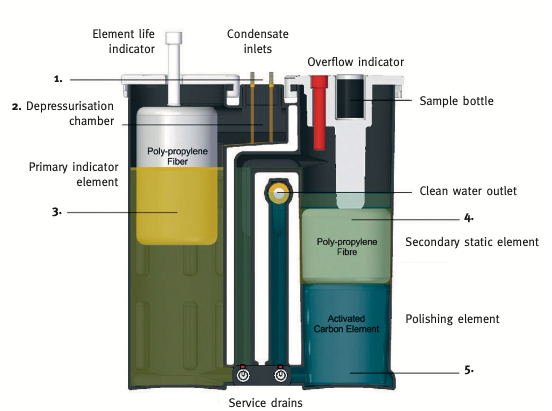

1. Condensate Inlet

Condensate containing oil enters the separator through inlet ports. The system is designed to accept condensate from any type of automatic drain used in a compressed air system.

2. Depressurization & Pre-Filtration

The condensate first enters a depressurization chamber, where a foam filter removes residual compressed air and stabilizes the flow. This allows the condensate to enter the treatment chambers at atmospheric pressure for optimal separation.

3. Primary Oil Adsorption Stage

Next, the condensate flows into the first treatment chamber, which contains a primary polypropylene fiber element. This element floats and is specifically designed to adsorb the majority of oil from the condensate. As the filter media becomes saturated, it gradually sinks – a unique design feature that provides a visual indicator of filter life and when replacement is needed.

4. Secondary Oil Adsorption Stage

The partially cleaned condensate then moves into a second chamber, where it passes through a static polypropylene element. This stage removes any remaining traces of oil to further purify the water.

5. Polishing Stage & Quality Check

In the final stage, the condensate flows through an activated carbon polishing filter, which removes remaining hydrocarbons and impurities. The cleaned water is discharged through the outlet port. A test valve and sample bottle are provided, allowing users to easily verify the water quality and ensure it meets environmental discharge standards.

| Model | 5 | 10 | 20 | 30 | 60 |

| Max. compressor capacity (m³/min.) | 5 | 10 | 20 | 30 | 60 |

| Max. oil adsorption (litres) | 5 | 10 | 15 | 25 | 50 |

| Inlet connections | ½” (2) | ½” (2) | ½” (2) | ½” (2) | ½” (2) |

| Outlet connection | 1” | 1” | 1” | 1” | 1” |

| Test valve | yes | yes | yes | yes | yes |

| Service drain | no | yes (2) | yes (2) | yes (2) | yes (2) |

| Overflow indicator | yes | yes | yes | yes | yes |

| Target output value | <10 ppm | <10 ppm | <10 ppm | <10 ppm | <10 ppm |

| Housing material | PE | PE | PE | PE | PE |

| Total recyclable | yes | yes | yes | yes | yes |

Key Benefits of Using an Oil/Water Separator

1. Environmental Protection

The separator prevents oil from polluting natural water sources, reducing the environmental footprint of your facility.

2. Legal Compliance

Most countries have strict laws governing the disposal of oily wastewater. An oil/water separator ensures compliance and avoids hefty fines.

3. Cost Savings

By separating oil before the wastewater reaches further treatment stages, companies can significantly reduce treatment costs and maintenance.

4. Equipment Protection

Oil in drain lines can damage pipes and wastewater treatment systems. Removing oil early helps extend the life of downstream equipment